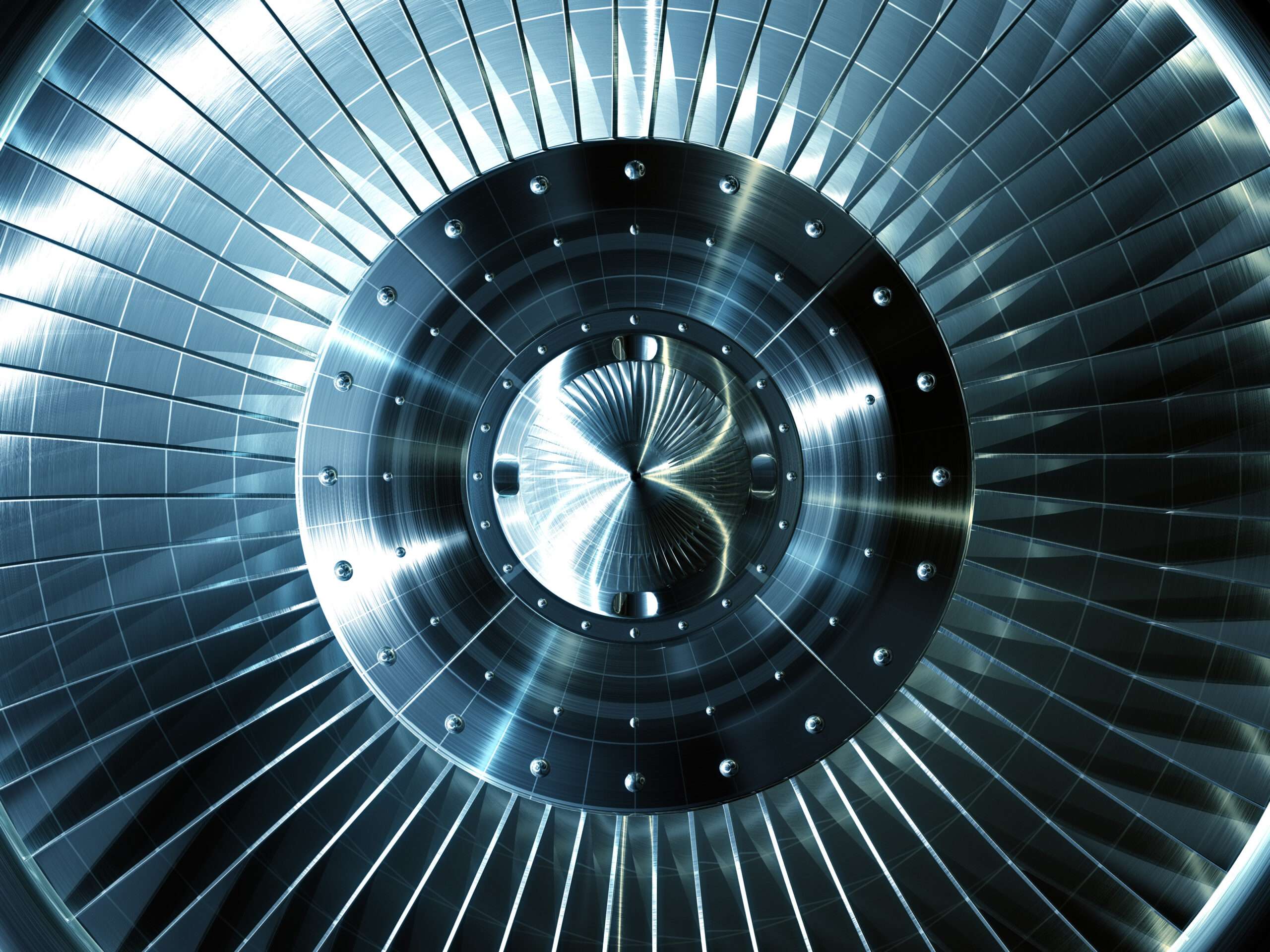

Land-based turbines

Land-based turbines

For many years, Aubert & Duval has been designing and manufacturing products intended for the most demanding industries, and particularly those in the energy production sector.

Aubert & Duval therefore assists its customers in the development and manufacture of materials and parts suited to the specific demands of land-based turbines. Intended for both small units (2-3 MW) and the most powerful and robust models (over 500 MW), these products comply with the strictest standards in terms of resistance to corrosion, fatigue, high temperature and mechanical stress. .

Our offer

- Stamped parts

- Bars

- Metal powders for additive manufacturing

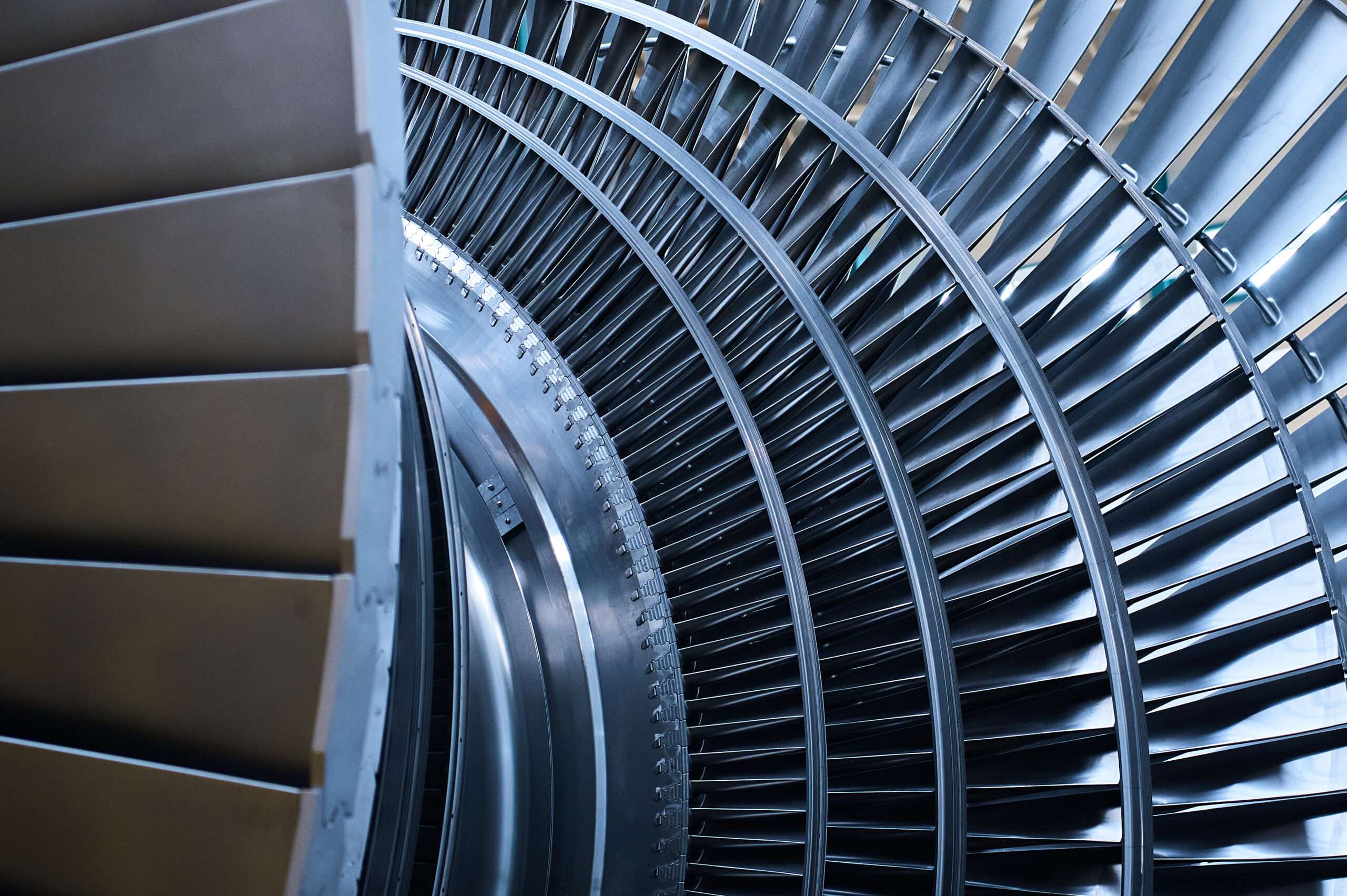

Stamped parts and parts created by hot isostatic pressing

Aubert & Duval controls the entire production chain from the creation and remelting of its nickel-based alloys, high-performance steels and titanium, to the transformation of these materials through forging-stamping or hot isostatic pressing.

Typical products

- Rotary-forged parts: small, medium and large parts for gas turbines, such as compressors and expanders, discs, spacers, shafts, rotor hubs and intermediate parts.

- Stamped parts for steam turbines.

- Hot Isostatic Pressing (HIP): rotating and fixed parts made from metal powders, for gas turbines and compressors.

- Nickel-and cobalt-based superalloy and stainless steel metal powders for additive manufacturing.

- Bars for blades, nuts and bolts, rods, etc.

- Special bars (round, flat, square) created in grades meeting particular specifications.

A preferential OEM and MRO supplier

Thanks to the combination of its expertise in metallurgy, its remarkable industrial capacities and its recognized manufacturing skills, Aubert & Duval contributes to developing the latest generation gas and steam turbines.

Working on the uniform structures of massive discs made of stamped superalloys or latest-generation wrought materials for extremely high-temperature steam turbines, Aubert & Duval is the partner of OEMs seeking high performances on a technical, economic and environmental level. .

Specific products and processes developed to overcome technical and economic challenges

- MLX®17 is a structurally hardened martensitic stainless steel with a breaking strength of up to 1,700 MPa, combined with a high level of toughness and resistance to fatigue, stress, corrosion and cracking. It helps to overcome one of the major challenges in improving efficacy and reducing construction costs in power stations by allowing the extension of the last stage blades.

- With MARVAL®X12H, MLX® 17 currently constitutes the highest quality level of steel grades for designing extended tip blades for steam turbines.

- AD730® is a highly innovative nickel-based superalloy. It is resistant to the highest temperatures (750°C/1,382°F) while retaining mechanical resistance to creep and fatigue at a competitive price.

It is suited to targeted applications: blades, vanes, and fixing systems for turbines, as well as rotating parts for gas turbines. It is suited to targeted applications: blades, vanes, and fixing systems for turbines, as well as rotating parts for gas turbines.

-

Land-based Brochure

PDFDownload (PDF, 5 MB)

These materials could also interest you

PER3

- Aero engine

- Disks

- High temperature

- Land turbine

- Common name : WASPALOY

- EU : NiCr20Co13Mo4Ti3Al

- USA : UNS:N07001

- AMS (Standard) : 5706, 5708, 5709

- AIR (Standard) : NC20K14

- NF-EN/NF-EN-ISO/NF-A (Symbol) : NiCr20Co13Mo4Ti3Al

- WL (Standard) : 2,4654

- ASTM (Grade) : N07001

- ASTM (Standard) : B637

- H + V

- UTS (N/mm²) : 1270

- A (%) : 25

PER706

- Disks

- Land turbine

- Common name : INCO 706

- EU : NiFe38Cr16Nb

- USA : UNS:N09706

- AMS (Standard) : 5703

- H + V

- UTS (N/mm²) : 1260

- A (%) : 18

PER718

- Aero engine

- Disks

- Land turbine

- Wheels

- Common name : INCO 718

- EU : NiCr19Fe19Nb5Mo3

- USA : UNS:N07718

- AMS (Standard) : 5662

- AIR (Standard) : NC19FeNb

- NF-EN/NF-EN-ISO/NF-A (Symbol) : NiCr19Fe19Nb5Mo3

- NF-EN/NF-EN-ISO/NF-A (Numerical) : 2,4668

- H + V

- UTS (N/mm²) : 1360

- A (%) : 18

PER72

- Aero engine

- Disks

- Impellers

- Land turbine

- Common name : UDIMET 720

- EU : NiCr18Co15TiMoAl

- H + V

- UTS (N/mm²) : 1530

- A (%) : 14